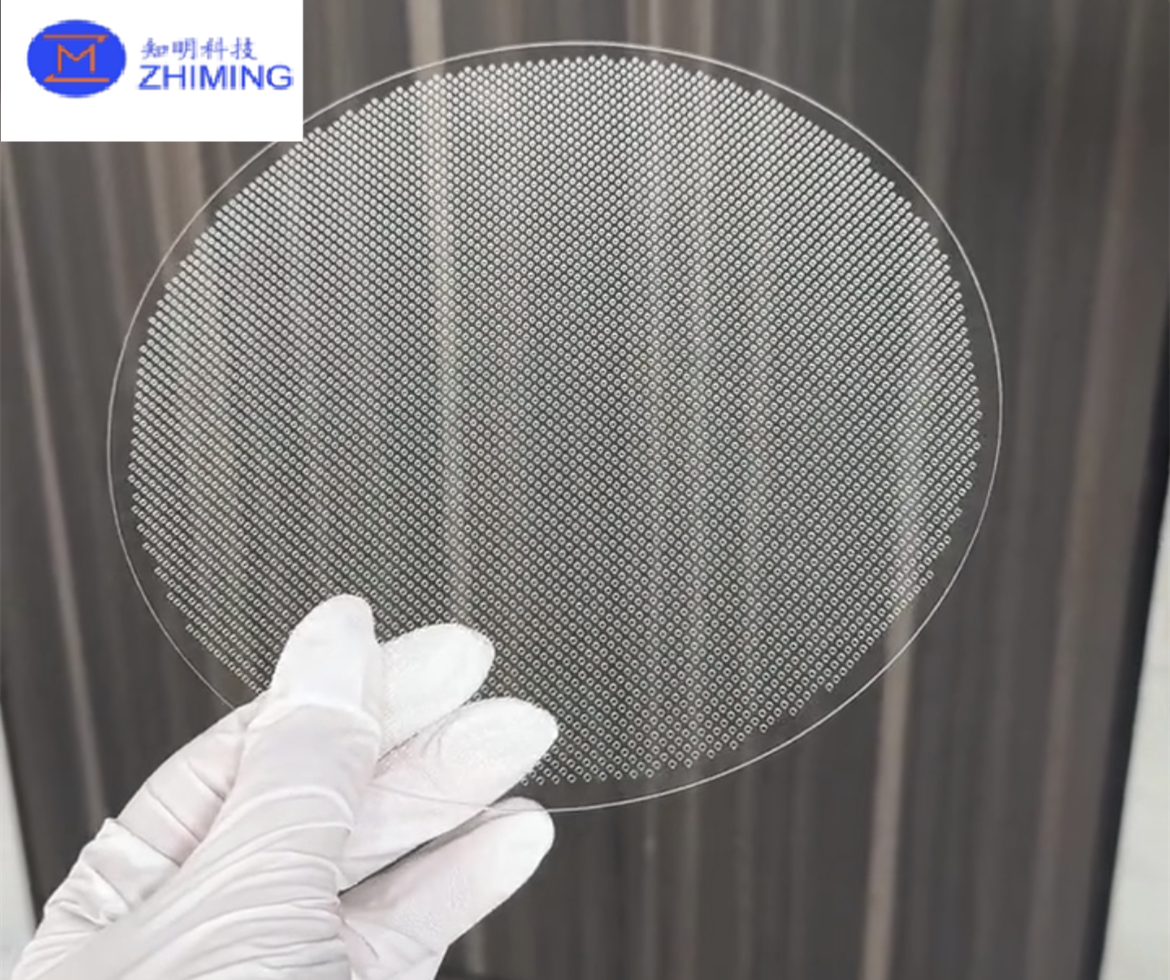

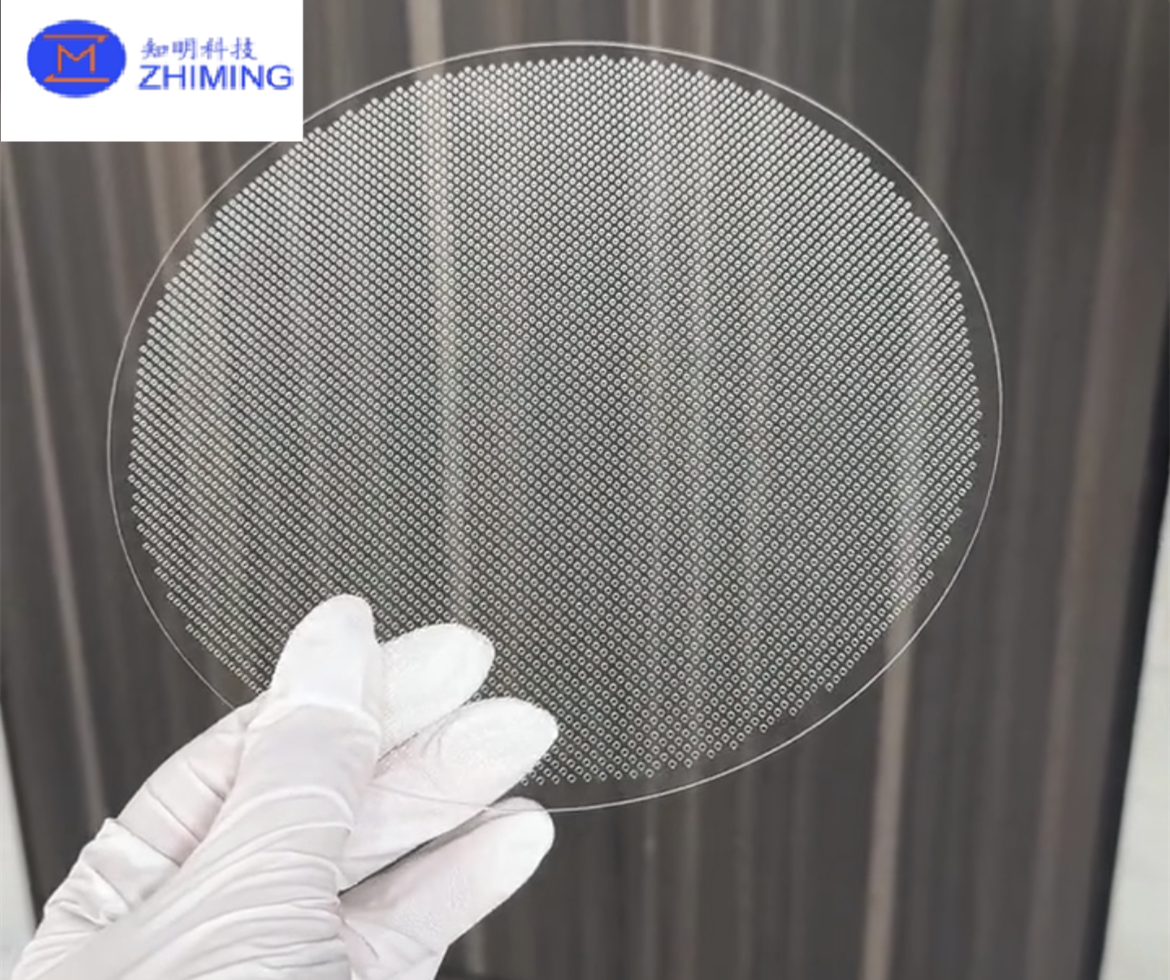

Through glass vias (TGV),JGS1 JGS2 sapphire BF33 quartz

Customizable dimensions, thickness can low as 100 µm.

Product abstract

Our innovative Through-Glass Vias (TGV) technologies revolutionize

electrical interconnect solutions, offering unprecedented

flexibility and performance across various high-tech industries.

Utilizing a selection of premium materials such as JGS1, JGS2,

sapphire, BF33, and quartz, our TGV products meet the stringent

demands of precision and durability.

Key Features and Advantages

Material Diversity: Our TGV offerings are crafted from high-quality materials

including JGS1 and JGS2 glasses, known for their exceptional

optical clarity and thermal stability; sapphire, which provides

outstanding hardness and scratch resistance; BF33 glass, renowned

for its thermal and mechanical properties; and quartz, appreciated

for its high purity and chemical resistance.

Customization: We provide fully customizable dimensions tailored to client

specifications, ensuring optimal integration with existing systems.

The thickness of our TGV products can be as low as 100 µm,

accommodating ultra-thin applications and enhancing device

compactness.

Enhanced Performance: The use of superior materials like sapphire and quartz in TGV

technology significantly improves device performance by enhancing

thermal management and reducing signal losses. This leads to more

efficient operation and prolonged device life.

Reliability and Durability: Our TGV products are engineered to withstand harsh conditions,

making them suitable for use in high-reliability sectors such as

aerospace, military, and medical devices. The resilience of

materials like sapphire and JGS glass ensures long-term reliability

and performance under extreme environmental conditions.

Technological Superiority: Incorporating advanced TGV technology enhances the electrical

performance by providing a direct pathway for signal and power

transmission through the substrate, which minimizes impedance and

increases the speed of electronic devices.

Market Flexibility: Suitable for a wide range of applications from consumer

electronics to specialized industrial equipment, our TGV products

are versatile and adaptable to both mass-market and niche

technological needs.

Our advanced TGV technology, coupled with our commitment to

customization and quality, makes us a leader in the field, ready to

meet the evolving challenges of modern industries. Choose our TGV

solutions for unparalleled performance and reliability.

Material characteristics

Our Through-Glass Vias (TGV) products are engineered using top-tier

materials such as JGS1, JGS2, sapphire, BF33, and quartz, each

chosen for its unique properties that enhance device functionality

and durability. These materials allow for customizable dimensions,

with thicknesses that can be reduced to as low as 100 µm,

facilitating integration into various device architectures without

compromising performance.

- JGS1 and JGS2: Both materials are known for their excellent optical

transparency and high thermal stability, making them suitable for

applications requiring minimal optical distortion and high

temperature resistance.

- Sapphire: This material is incredibly durable and offers

exceptional scratch resistance and hardness, ideal for environments

where physical wear and tear are concerns.

- BF33: Known for its robust mechanical properties and thermal

stability, BF33 is optimal for applications that undergo frequent

temperature fluctuations.

- Quartz: With its high purity and low thermal expansion, quartz is

excellent for high-precision applications that require stable,

reliable performance under thermal stress.

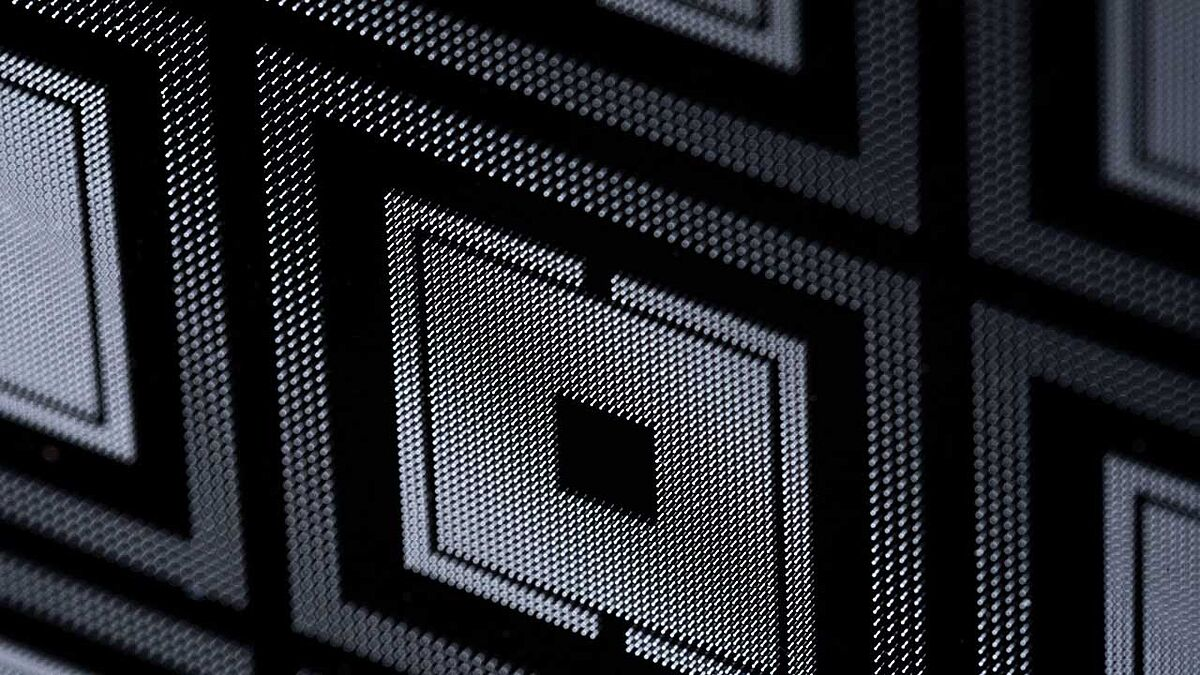

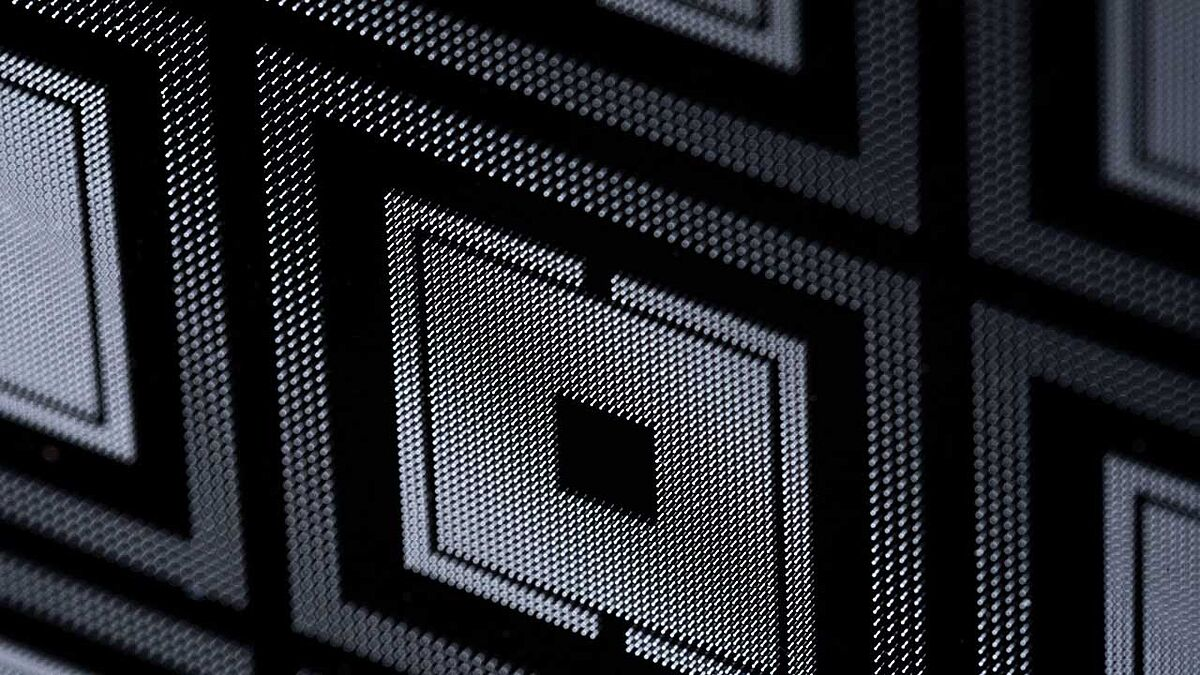

Image

Working Principle of TGV Technology

Glass Substrate Selection: Initially, suitable glass materials such as JGS1, JGS2, BF33, or

quartz are selected. These materials are chosen for their excellent

optical, electrical, and thermal stability characteristics.

Drilling: Techniques such as laser drilling, ultrasonic drilling, or

photolithography are used to precisely create vias in the glass

substrate. The diameter and placement of these vias are controlled

according to design requirements.

Metalization of Vias: To enable the vias to conduct electrical signals, their inner

walls are coated with a metal layer. Common metallization materials

include copper, tungsten, or gold. The metallization process may

involve chemical vapor deposition (CVD), physical vapor deposition

(PVD), or electroplating.

Packaging and Interconnection: Once metallization is complete, the vias in the glass can

directly connect to circuits on semiconductor chips or other

electronic components. This vertical interconnection approach helps

reduce wiring space and enhance integration.

Testing and Encapsulation: After metallization and interconnection are complete, the entire

assembly is tested to ensure that the electrical performance meets

specifications. Subsequently, the assembly is encapsulated to

provide physical and environmental protection.

Advantages of TGV Technology:

Reduced Signal Path Length: By making direct connections through the glass substrate, signal

path length is significantly reduced, thereby lowering signal delay

and improving processing speed.

Increased Device Density and Functional Integration: TGV allows for more compact layouts, aiding in the increase of

functional density in electronic devices.

Enhanced Thermal Management: Metallized vias effectively conduct heat, aiding in improved

thermal management of the chip.

Enhanced Dvice Reliability: TGV technology enhances overall device reliability and durability

by reducing the number of interconnections and their complexity.

TGV technology provides an efficient and reliable interconnection

solution for modern microelectronic devices, particularly suitable

for applications requiring high performance and reliability, such

as aerospace, military, and advanced communication systems.

Application Summary

Through-Glass Vias (TGV) technologies are reshaping the landscape

of various high-tech industries by providing innovative,

customizable, and high-performance interconnect solutions. Our

advanced TGV products utilize top-tier materials such as JGS1,

JGS2, sapphire, BF33, and quartz, each chosen for their unique

properties to meet diverse application needs across different

sectors.

Aerospace and Aviation:In aerospace applications, reliability and precision are paramount.

Our TGV technology, using materials like sapphire and BF33 glass,

offers exceptional durability and resistance to extreme

environmental conditions. This ensures reliable performance in

critical systems such as avionics, satellite communications, and

spacecraft instrumentation, where failure is not an option.

Military and Defense:For military applications, our TGV products provide robust and

secure communication links in equipment exposed to harsh

operational conditions. The thermal and mechanical stability of JGS

glasses makes them ideal for use in ruggedized electronics,

targeting systems, and secure communication devices that require

consistent performance in varying climates and under physical

stress.

Medical Devices:In the medical sector, the precision and biocompatibility of

materials like quartz and sapphire are crucial. Our TGV solutions

enhance the functionality of diagnostic and therapeutic devices,

such as imaging systems and wearable health monitors. The

ultra-thin, customizable dimensions of our TGV products allow for

their integration into compact medical devices, improving patient

comfort and device efficacy.

Consumer Electronics:Our technology significantly benefits consumer electronics by

enabling thinner, more efficient devices. The customizable

thickness down to 100 µm allows for sleeker designs in smartphones,

tablets, and wearable technology. The superior electrical

performance facilitated by our TGVs enhances device speed and

battery life, offering consumers more powerful and reliable

gadgets.

Industrial and Scientific Instrumentation:In industrial and scientific applications, the chemical resistance

of quartz and the optical clarity of JGS glasses make our TGV

products ideal for sensors and instrumentation in harsh chemical

environments or precision optical systems. They provide reliable

and accurate data transmission, essential for industrial automation

systems and laboratory equipment.

Our TGV technologies, supported by a range of high-quality

materials and customization options, are pivotal in advancing the

capabilities of devices across multiple sectors. By choosing our

TGV solutions, industries can leverage the benefits of enhanced

performance, increased reliability, and greater flexibility, ready

to meet the demands of modern technology and innovation.

Key words:

Through-Glass Vias (TGV)

TGV glass

TGV sapphire

Interconnect Solutions

Advanced Semiconductor Technology