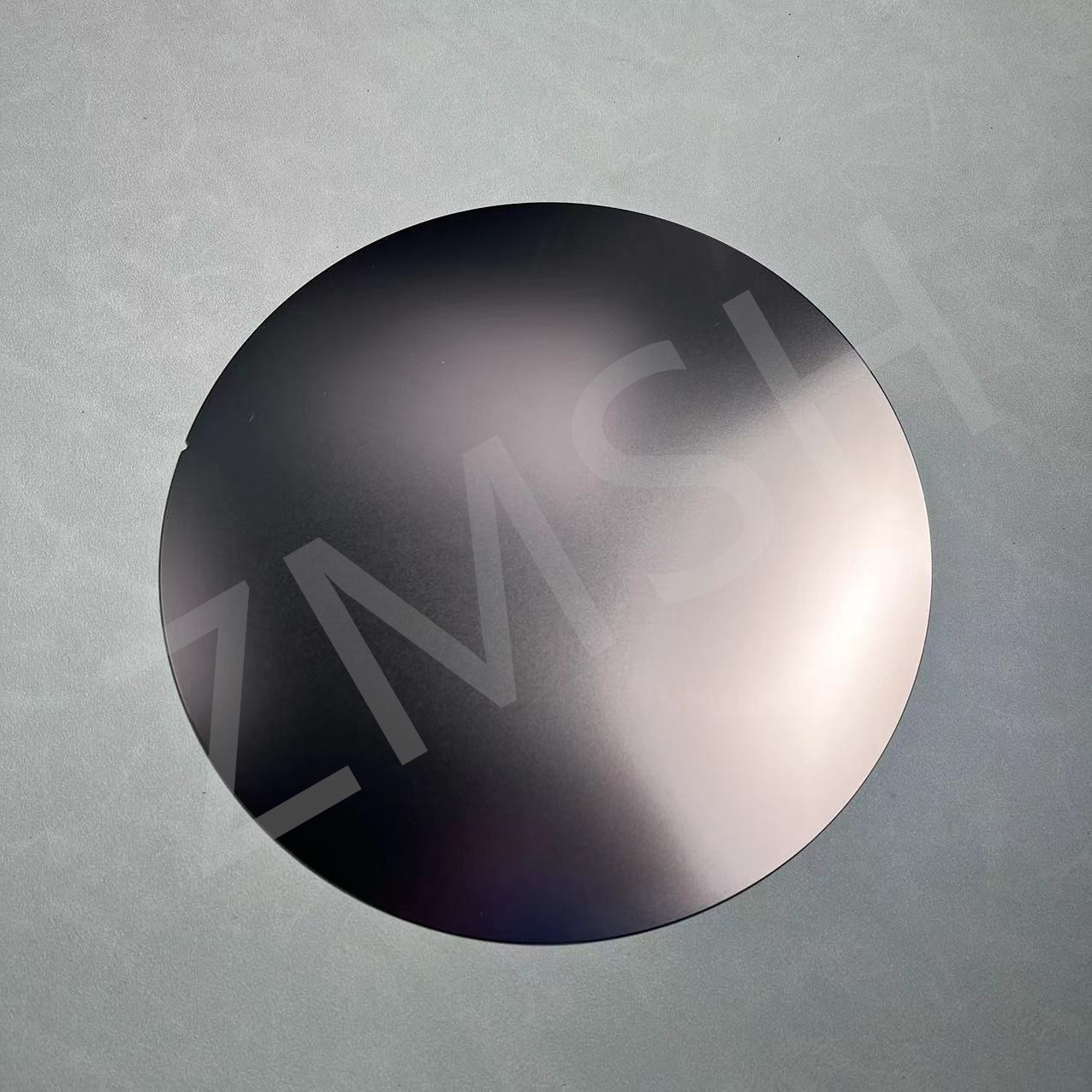

Silicon Carbide (SiC) Optical Lens – Infrared & Laser Applications

Product Overview of Silicon Carbide (SiC) Optical Lens

Silicon Carbide (SiC) lenses are advanced optical components

designed for demanding environments requiring high thermal

stability, exceptional hardness, and excellent infrared

transmission. Compared with traditional glass or sapphire lenses,

SiC offers an unbeatable combination of mechanical strength,

thermal shock resistance, and broad spectral performance.

Manufacturing Principle of Silicon Carbide (SiC) Optical Lens

SiC lenses are manufactured through the following processes:

Powder Synthesis & Sintering

High-purity SiC powder is formed and densified using hot-press

sintering (HPS) or chemical vapor deposition (CVD), ensuring high

density and purity.

Precision Machining

Due to the material's extreme hardness, ultra-precision diamond

grinding and CNC polishing are employed to achieve optical surface

accuracy (up to λ/10).

Surface Finishing & Coating

Final finishing may include plasma polishing, AR coatings (for

infrared or visible light), or protective films to reduce

reflectance and enhance durability.

Technical Specifications of Silicon Carbide (SiC) Optical Lens

| Parameter | Specification |

|---|

| Material | Sintered SiC / CVD SiC |

| Diameter Range | 5 mm – 200 mm |

| Surface Accuracy | λ/10 @ 633 nm |

| Surface Roughness | < 1 nm RMS (after super-polishing) |

| Transmission Range | 0.4 μm – 5 μm (uncoated); up to 15 μm with coating |

| Thermal Expansion Coeff. | 4.0 × 10⁻⁶ /K (25°C) |

| Thermal Conductivity | ~ 120 – 200 W/m·K |

| Hardness | ~ 9.5 Mohs |

| Refractive Index | ~ 2.65 @ 1 μm |

Applications of Silicon Carbide (SiC) Optical Lens

SiC lenses are used in extreme optical environments where other

materials fail:

Infrared Imaging Systems (e.g., defense-grade IR sensors)

High-Power Laser Optics (for CO₂ or solid-state lasers)

Space and Aerospace Systems (due to resistance to thermal shock)

Semiconductor Equipment (such as UV exposure or ion implantation)

Spectroscopy and Analytical Devices

High-speed optical scanners in LiDAR

FAQ of Silicon Carbide (SiC) Optical Lens

Q1: Why choose SiC over sapphire or optical glass lenses?

A: SiC offers superior mechanical strength, lighter weight, higher

thermal conductivity, and better resistance to extreme conditions.

It outperforms sapphire in thermal shock and has a broader usable

IR range than standard glasses.

Q2: Can SiC lenses be coated for visible or infrared transmission?

A: Yes, anti-reflective coatings such as DLC, ZnSe, or MgF₂ can be

applied to tailor performance for specific wavelengths.

Q3: What’s the lead time for custom SiC lenses?

A: Typically 4–8 weeks, depending on shape complexity, size, and

surface specs.

Q4: Is CVD-SiC better than sintered SiC?

A: CVD-SiC offers superior purity and is preferred for space optics

and extreme UV applications, while sintered SiC is more

cost-effective for general use.

Q5: Do you support aspherical or off-axis SiC lens shapes?

A: Yes, we provide custom-shaped lenses, including cylindrical,

toroidal, and freeform surfaces.