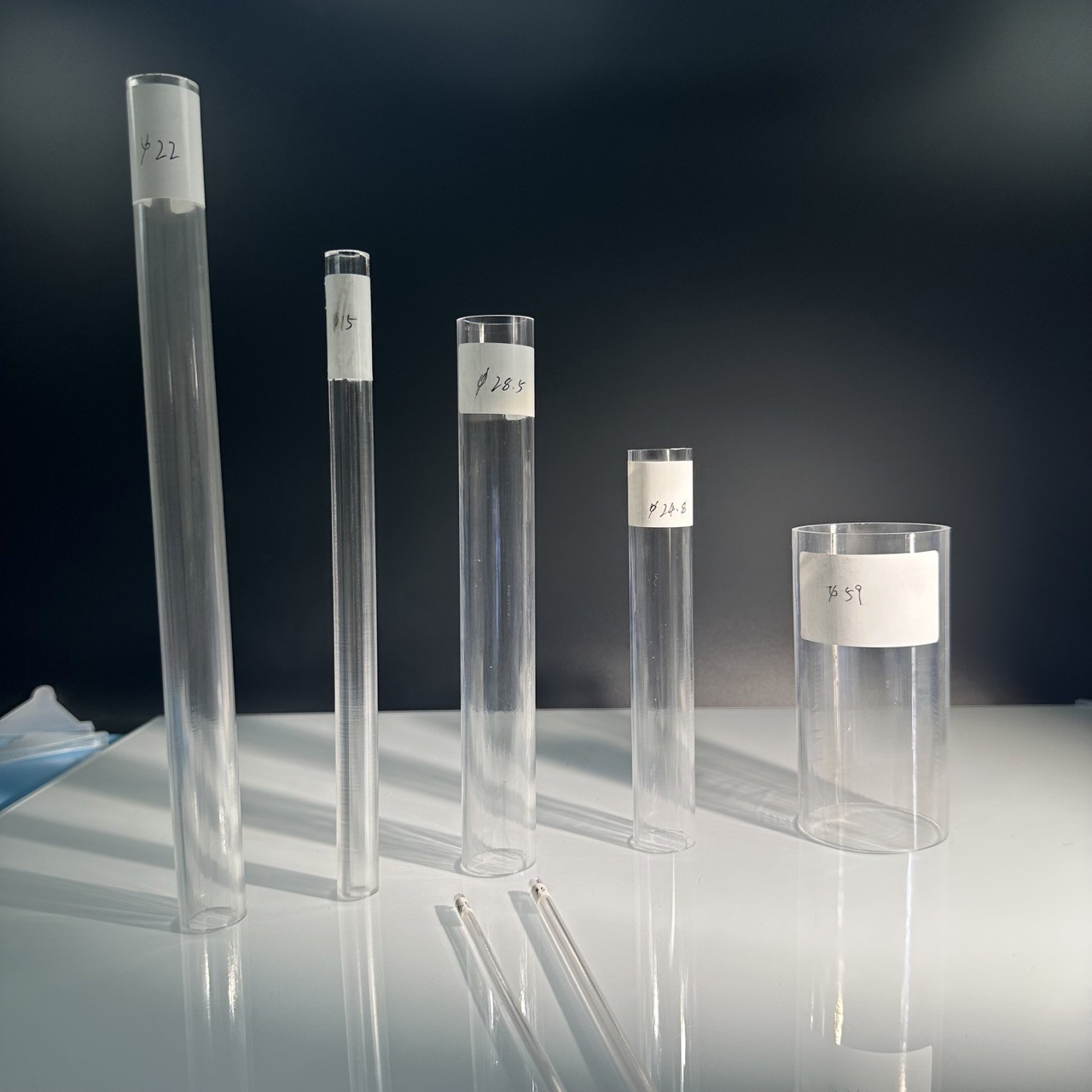

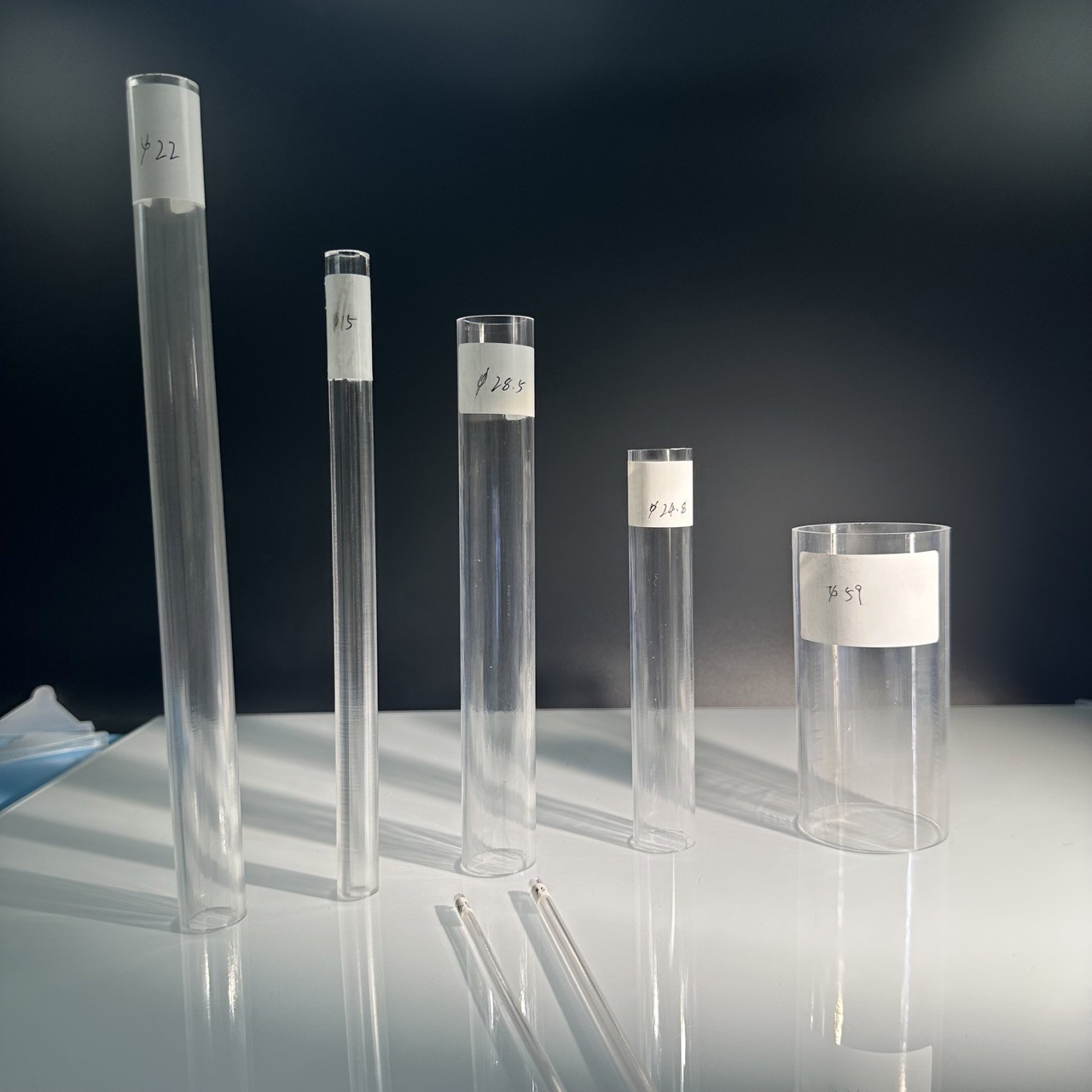

Product Introduction Of Sapphire Tubes

sapphire tubes are produced using advanced growth technologies that

result in high-purity, optically uniform single crystals. These

tubes are free of growth striations or visible internal defects,

making them ideal for demanding applications in optics, photonics,

and medical instrumentation. They offer excellent transparency

across visible to mid-infrared wavelengths.

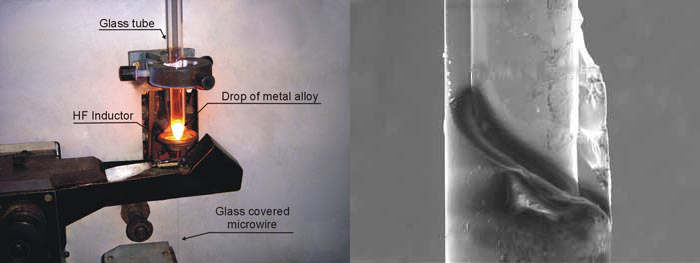

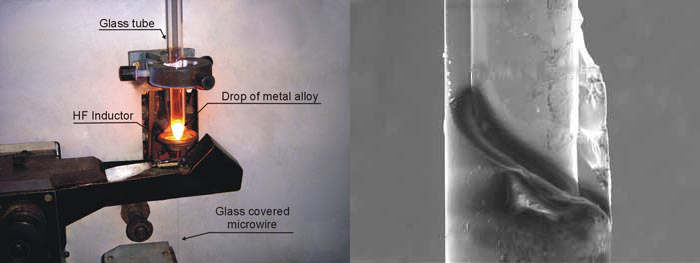

Working Principle Of Sapphire Tubes

To avoid striations, sophisticated control over thermal gradients,

pulling speed, and impurity concentration is required during

crystal growth. Advanced techniques such as modified KY, horizontal

directional solidification, or EFG are used. Slow growth and

post-annealing ensure refractive index uniformity and high optical

quality.

Applications Of Sapphire Tubes

Industrial Inspection Windows: Transparent windows for

high-temperature furnaces or plasma chambers.

Optical Fiber Sheathing: Protection of sensitive optical/fiber

components in harsh environments.

High-Temperature Sensor Housing: Enclosure for thermocouples or

optical temperature sensors.

Medical Devices: Fluid delivery systems or probe housings in

high-sterility environments.

Military & Aerospace: Windows and monitoring tubes for missiles or

spacecraft.

Q&A Of Sapphire Tubes

Q1: What is the maximum temperature a sapphire tube can withstand?

A1: Sapphire tubes can withstand up to 1600°C in air and over

2000°C in inert or vacuum environments.

Q2: Is sapphire electrically conductive?

A2: No, sapphire is an excellent electrical insulator, suitable for

high-voltage applications.

Q3: Is it suitable for vacuum or pressure environments?

Yes. Sapphire’s excellent hermeticity and mechanical strength make

it ideal for such applications.

Q4: Can AR coating or anti-reflective treatment be applied?

Yes. Multi-layer AR coatings can be customized to enhance optical

performance.

Related products

99.995% Al2O3 Transparent Sapphire Tube With High Tolerance

Translucency

Sealed Sapphire Tube Aluminum Oxide Polished Single Crystal

Corrosion-Resistant