SHANGHAI FAMOUS TRADE CO.,LTD

SHANGHAI FAMOUS TRADE CO.,LTD. locates in the city of Shanghai,

Which is the best city of China, and our factory is founded in Wuxi

city in 2014.

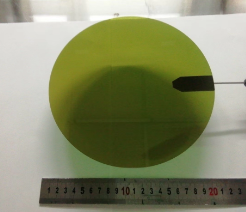

We specialize in processing a varity of materials into wafers,

substrates and custiomized optical glass parts.components widely

used in electronics, optics, optoelectronics and many other fields.

We also have been working closely with many domestic and oversea

universities, research institutions and companies, provide

customized products and services for their R&D projects.

It's our vision to maintaining a good relationship of cooperation

with our all customers by our good reputatiaons.